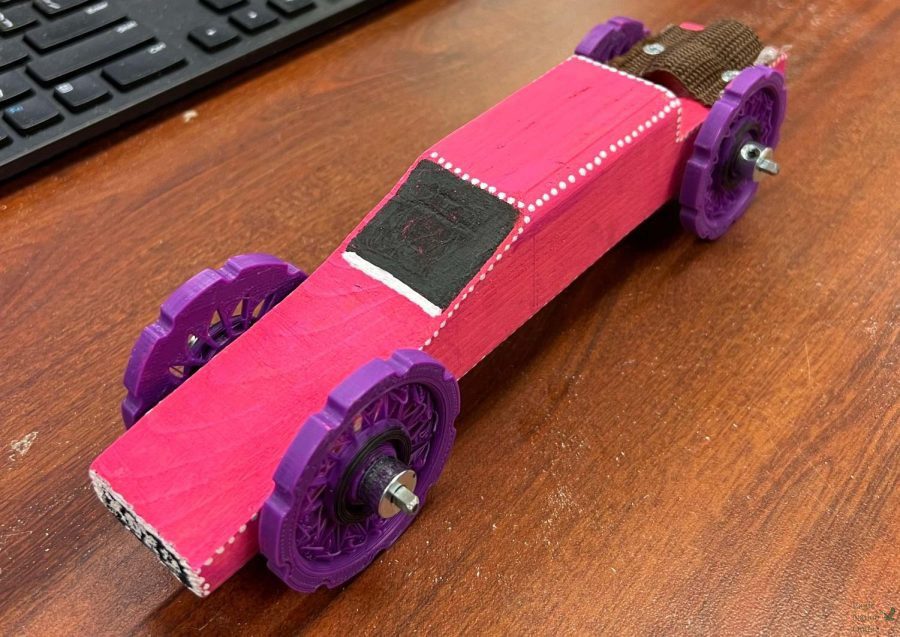

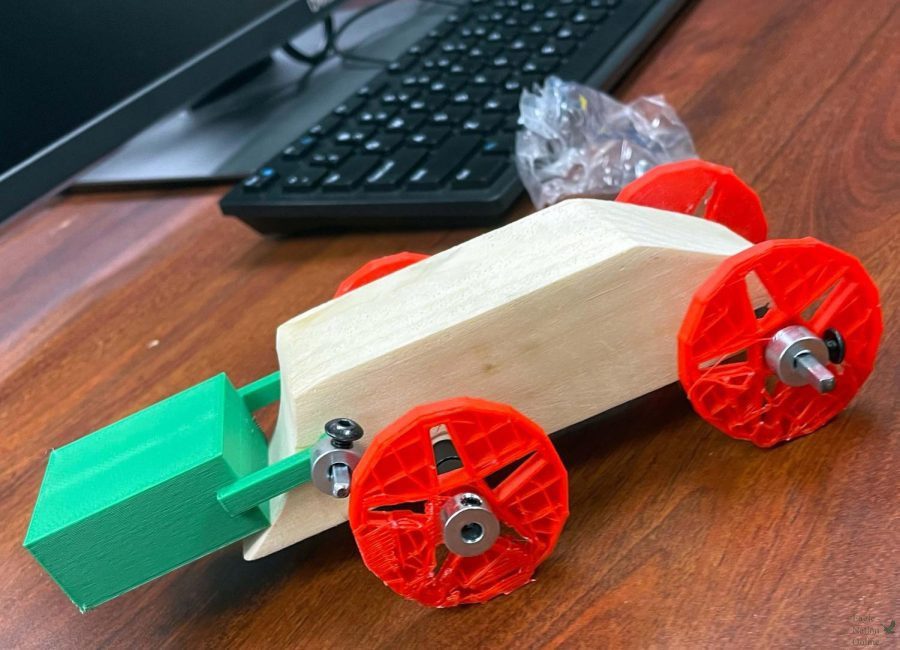

Engineering races carbon dioxide cars

The engineering classes, taught by Jenny Anderson and Daniel Geiter, built and designed carbon-dioxide powered cars. The students could 3D-print materials for their cars. Then, they drove their vehicles and reflected on their project’s effectiveness.

Donate to Eagle Nation Online

$300

$2000

Contributed

Our Goal

Your donation will support the student journalists of Prosper High School. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.

About the Contributor

Amanda Hare, Executive Editor-in-Chief and Executive News Editor

Amanda Hare is a senior at Prosper High School and works as Executive Editor-in-Chief for Eagle Nation Online. She competes in UIL Journalism and has won awards in all five events including state runner-up headline writer twice. Amanda enjoys listening to music -- specifically Taylor Swift -- dancing, spending time with her friends and playing with her dog. After high school, Amanda plans to attend Texas A&M University in College Station to major in marketing and business honors and minor in journalism.

2022 TAJE Texas Journalist of the Year

2019, 2021 UIL State Headline Writing Champion Runner-Up

2022 UIL State Meet: 3rd place Headline Writing, 4th place News Writing, 7th place Editorial Writing

UIL Headline Writing Regional Awards:

2019: 2nd place

2020: 2nd place

2021: 3rd place

UIL Editorial Writing Regional Awards:

2020: 2nd place

2021: 4th place

20 Best of SNO publications

2021 National NSPA Story of the Year Honorary Mention

2021 National NSPA Top 10 Best of Show Podcast

2021 TAJE Best of Texas: Excellent Story Portfolio, Superior News-Feature Story, Honorable Mention Headline Writing

2021 TAJE Fall Fiesta: Superior Headline Writing, Superior Interview Podcast, Excellent Video News Story, Excellent Video Feature Story

2022 TAJE Best of the Best: 3rd place Online News Portfolio

2022 TAJE Best in Texas: Excellent Interview Podcast, Superior Story Portfolio, Honorable Mention News Story, Honorable Mention Feature Story, Excellent In-Depth Package, Excellent Entertainment Feature, Excellent Headline Writing

2022 NSPA Best of Show: 7th place Editorial Board Leadership, 4th place Podcast

2022 ILPC 6A Awards: 2nd place Sports Feature Story, 3rd place Feature Writing, 3rd Place Entertainment Review, 1st Place In-Depth News/Feature Package, 1st Place Photo Slideshow, 1st Place Video Story, 1st Place Multimedia Package, Honorable Mention Portrait, 3rd place Headlines

2022 Tops in Texas Awards: Photo Slideshow, Multimedia Package

2021 TAJE Student Advisory Council Member

2020-2022 PHS Newspaper Student of the Year

NSPA Student Journalist National Honor Roll

Quill and Scroll Honor Society Member

Honors & Awards:

2022 TAJE Texas Journalist of the Year

2019, 2021 UIL State Headline Writing Champion Runner-Up

2022 UIL State Meet: 3rd place Headline Writing, 4th place News Writing, 7th place Editorial Writing

UIL Headline Writing Regional Awards:

2019: 2nd place

2020: 2nd place

2021: 3rd place

UIL Editorial Writing Regional Awards:

2020: 2nd place

2021: 4th place

20 Best of SNO publications

2021 National NSPA Story of the Year Honorary Mention

2021 National NSPA Top 10 Best of Show Podcast

2021 TAJE Best of Texas: Excellent Story Portfolio, Superior News-Feature Story, Honorable Mention Headline Writing

2021 TAJE Fall Fiesta: Superior Headline Writing, Superior Interview Podcast, Excellent Video News Story, Excellent Video Feature Story

2022 TAJE Best of the Best: 3rd place Online News Portfolio

2022 TAJE Best in Texas: Excellent Interview Podcast, Superior Story Portfolio, Honorable Mention News Story, Honorable Mention Feature Story, Excellent In-Depth Package, Excellent Entertainment Feature, Excellent Headline Writing

2022 NSPA Best of Show: 7th place Editorial Board Leadership, 4th place Podcast

2022 ILPC 6A Awards: 2nd place Sports Feature Story, 3rd place Feature Writing, 3rd Place Entertainment Review, 1st Place In-Depth News/Feature Package, 1st Place Photo Slideshow, 1st Place Video Story, 1st Place Multimedia Package, Honorable Mention Portrait, 3rd place Headlines

2022 Tops in Texas Awards: Photo Slideshow, Multimedia Package

2021 TAJE Student Advisory Council Member

2020-2022 PHS Newspaper Student of the Year

NSPA Student Journalist National Honor Roll

Quill and Scroll Honor Society Member